Value addition and processing of commodities

Rice Processing

The rice market in rice producing areas is dominated by middlemen/vendors as there is no structured market for the commodity. Most of the commercial villages have inadequate storage and milling facilities which force farmers to sell their unpolished rice to middlemen/vendors. Rice milling is one simple process that farmers could adopt and sell their rice at a higher price. In a rice milling process, husk and bran removal are done in one pass and milled or white rice is produced directly out of paddy.

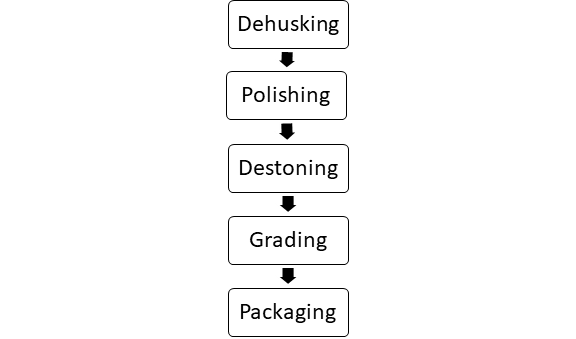

Figure 1: Rice milling process

Material and Methods

- Paddy rice

- Rice milling machine

- De-stoning machine

- Grading machine

- Packaging materials

Procedure for Rice milling

Step 1: De-husking

Rice de-husking is a process of removing the husk from the paddy rice. The main product is brown rice and the by-product from this process is the rice husk which might be used as animal bedding or fuel.

Rice husks and brickets made from rice husks

Step 2: Polishing

In the polishing process, the bran and the embryo are removed from the de-husked rice. The main product is polished white rice and the by product is bran and embryo. Rice bran is the most valuable by-product of rice milling industry as it is used as animal feed. It contains 12-15% protein, 14-20% oil if the paddy is raw and 18-25% if parboiled, and is a rich source of B-group vitamins.

Rice bran; a by-product of rice polishing.

Step 3: Destoning

This is the removal of stones and other impurities from white rice. The main product is stone free white rice, with small stones as by product.

Stone-free rice

Step 4: Grading

Grading rice is a process of separating broken rice kernels from the milled rice kernels. The milled rice contains whole grains, broken grains of different sizes as well as some bran and dust. Grading give rice that has a very low percentage of broken rice.

Step 6: Packaging

The final stage of rice processing where by rice is packed and sealed in appropriate packages ready for market.

Packaged kilombero rice