Value addition and processing of commodities

Cassava Processing

The root is not the only part of the plant that can be put to good use. Cassava leaves can be cooked as a vegetable. The green part of the upper stem is fed to cattle and buffaloes, and the leaf-blades to pigs and chickens. Stumps are burned as fuelwood, and woody stems are ground-up and used as substrate for growing mushrooms. Cassava is a high source of carbohydrates and it is in the group of staples on the Malawian six food groups chart.

Fresh cassava roots are highly perishable and contain 65–70 percent moisture, whereas high-quality cassava flour (HQCF) contains only 10–12 per cent moisture and has a much longer shelf life. Reduction of moisture is a key step in processing cassava roots into HQCF and must be done quickly to avoid lowering product quality.

MATERIALS AND METHODS

Materials

- Fresh cassava roots

- Water

- Knives

- Grater

- Drier

Methods

Step 1:- wash the fresh cassava roots soon after harvesting to remove all dirt

Step 2:- peel the cassava using knives to remove the outer skin

Step 3:- grate the cassava to increase the surface area so as to facilitate quick drying

Step 4:- press the grated cassava using a jack press or a cheese cloth to remove excess water.

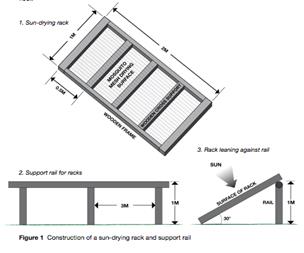

Step 5:- Spread the grated cassava on special drying racks that have a porous drying surface to improve airflow. The drying surface for these racks is made from mesh stretched over a rectangular wooden frame 2m-long by 1m wide (see Figure below). The main frame is made from timber (8cm x 2cm section is sufficient) of sufficient strength to maintain shape when wet product is loaded on to the mesh. The four parts of the frame are screwed together to make maintenance easier.

cassava drying racks

Step 6:- For bitter varieties the peeled cassava is firstly soaked in water for 3 days to remove some toxins. The soaking often leads to fermentation which gives it a good flavor.

Step 7: The dried grated cassava can later be milled into flour and packaged

Step 8: Grated cassava can also be packaged and sold without further milling

Dried cassava (Makaka) processing

Step 1: Wash the cassava roots thoroughly after harvest

Step 2: Peel the cassava roots using knives or cassava peeling machines

Step 3: Dry the peeled roots on mats (sun-drying), using solar drier or mechanical drier.

Step 4: When completely dried, package and store in a cool dry place

Step 5: For bitter cassava varieties soaking in water for 3 days is needed