Value addition and processing of commodities

Groundnut Processing

Groundnut (Arachis hypogaea L.) is one of the most important food legumes in Malawi’s subsistence farming communities. Groundnut has a significant economic importance to farmers; it accounts for more than a third (approximately 40%) of small-scale farmers’ income. Groundnut is considered as an important component of the Malawian diet because of its high nutritional value, it is an important source of fat and protein for those without regular, affordable access to meat, eggs or dairy products.

Groundnuts are consumed in different forms in the country- raw, roasted, fresh boiled or mixed with beans as relish. Groundnuts in Malawi are processed into different products such as groundnut flour, roasted groundnuts and peanut butter.

Peanut butter is a peanut paste or spread made from ground dry roasted peanuts. It often contains additional ingredients that modify the taste or texture, such as salt, sugar, stabiliser or emulsifiers. The processes generally consist of the following unit operations: shelling, sorting, dry blanching, followed by fine grinding up into a creamy paste.

MATERIALS AND METHODS

Materials

- Groundnuts

- Sugar (optional)

- Salt

- Stabiliser

- Weighing scale

- Oven

- Peanut butter processing machine

- Winnower

- Plastic pail

- Packaging materials (plastic bottles)

Procedure for peanut butter processing

Step 1: Unshelled nuts must be sorted to remove rotten pods, mouldy pods, insect infected pods and broken pods. Sorting helps to reduce aflatoxin contamination in groundnuts and peanut butter.

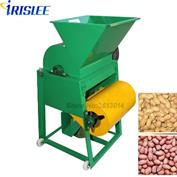

Step 2: Shelling of groundnuts. This can be done manually or using a groundnut shelling machine.

Step 3: Sorting of shelled nuts must be done to remove rotten, mouldy, broken, insect infested and discolored grains. This further helps improve quality and safety of peanut butter by reducing aflatoxin load. Broken grains get burnt easily and faster while roasting which might reduce the quality of peanut butter thus the need to sort them out.

Step 4: Winnowing is done to clean the grains from dust and any foreign materials. Stones, dust, groundnut husks that have find their way into the groundnuts must be winnowed out to produce quality peanut butter.

Step 5: Blanching is done to facilitate de-skinning and sorting out of discoloured grains. Discoloured grains might not be visible before splitting the groundnuts, thus blanching helps facilitate de-skinning and sorting out of discolored grains.

Step 6: Sorting and winnowing is done to remove discolored grain, peanut skins and the peanut heart. Peanut heart will get burnt reduce the quality of the peanut butter.

Step 7: Roast at 1900C for 15 minutes until golden brown. This might be done using a peanut roaster, the oven or open fire.

Step 8: If desired, mix 1 tea spoon of salt and sugar to 10 kg of groundnuts

Step 9: Grind in a peanut butter machine

Peanut butter machine

Step 10: Package in sterile bottles.