Value addition and processing of commodities

Ginger Powder Processing

Ginger is a medicinal plant that has been widely used all over the world for a wide range of unrelated ailments including arthritis, cramps, rheumatism, sprains, sore throats, muscular aches, pains, constipation, vomiting, hypertension, indigestion, dementia, fever and infectious diseases. It has direct anti-microbial activity and thus can be used in treatment of bacterial infections.

Ginger powder is a product where the only ingredient is the ginger rhizome harvested at full maturity (8-9 months after planting). Dry Ginger is one of the most popular spice consumed in various forms as medicine, or spice.

MATERIALS AND METHODS

Materials

- Fresh ginger

- Drying medium (solar drier/mechanical drier)

- Grinding machine

- Knives

- Buckets

- Packaging materials (capped plastic containers or polyethylene bags)

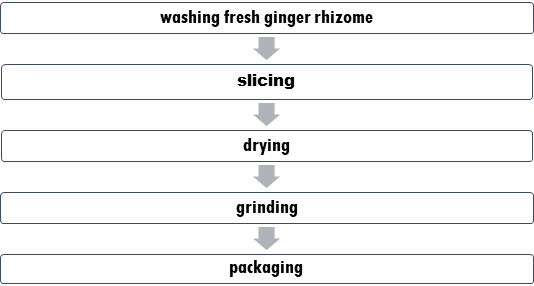

Method (Procedure for ginger powder processing)

Step 1: Wash ginger rhizomes with clean water immediately after harvest to remove all the soil from the farm and ensure a pale colour. Washing can be done under running water, in buckets or using a mechanical washer. Washing ensures that the final product maintains quality and is safe for consumption. The wet rhizomes should not be allowed to lie in heaps for too long as they will begin to ferment.

Brush washing machine for ginger and potatoes

Step 2: Cut rhizomes into thin slices. This can be done using a knife or mechanical slicers. This operation increases the surface of the ginger exposed to the drying condition and results in faster drying.

Ginger slicing machine

Step 3: Dry the peeled and/or sliced pieces of ginger using a drying medium to 7 – 12% moisture content and this will result in loss of 60 – 70% weight of the rhizomes. Different drying mediums might be used to dry ginger; sun-drying, solar drying and mechanical drying. However, mechanical drying and is faster and produces a clean product.

Mechanical dryer and solar drier

Step 4: Grind the dried ginger slices to powder using a grinder. A grinder might be in form of a blender or a high performance grinding machine.

Step 5: Package in sterile containers. The principal roles of food packaging are to protect food products from outside influences and damage, to contain the food, and to provide consumers with ingredient and nutritional information.

Figure 2: Process flow for ginger powder